- Home

- >

- Service Package

- >

- Development

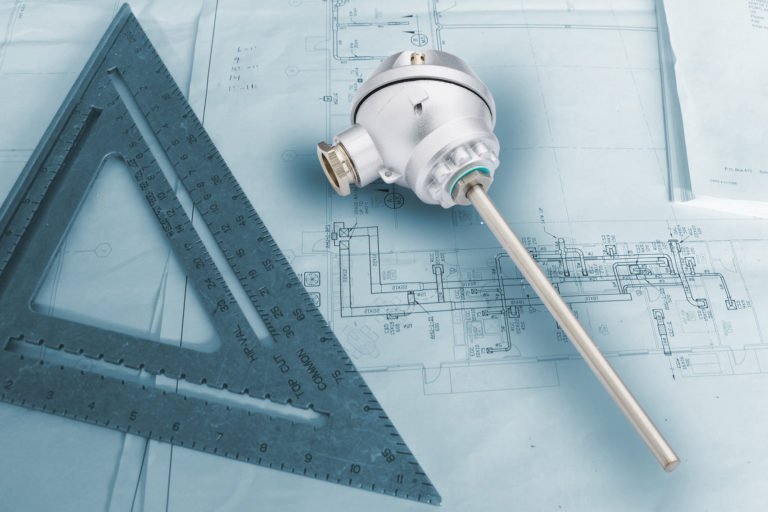

Development

To develop the ideal temperature sensor for your application, a number of important points must be taken into consideration. Based on our technical know-how and our experience from numerous customer projects, we offer you competent advice on new projects, cost saving projects or the exploration of quality improvement potentials.

According to your application-specific requirements, you will receive the appropriate housing geometry and mounting type, the suitable sensor type (thermistor, Pt) with the correct characteristic curve and tolerance class, as well as the specification-compliant design of the protection class and the electrical connection option via an open cable or the connector of your choice.

The development process includes

- exact elaboration of the specification

-

construction of your temperature sensor

including the creation of the technical drawing - Assembly of samples and prototypes

- Realization of all qualification measures

- planning of the assembly line for the later series production

The most important components of your temperature sensor solution

We develop our temperature sensors in such a way that later in series production all critical production steps, such as electrical connections or potting processes, can be automated. This is the only way to produce larger quantities in series production with the necessary high reproducibility. Ensuring quality in series production already begins with the start of a development, not with the SOP (Start of Production).

Temperature dependent resistance type

- Measuring range: Which temperature range must be covered?

- Accuracy: How precise the sensor has to measure?

- Response time: How fast (T63, T90) must it react to temperature changes?

- Characteristics: Are certain NTC, PTC characteristics predefined or should standard Pt resistors be used?

Probe Design

- Design: Screw-in or plug-in sensor; sensor with plug or open cable end?

- Process connection: How is the sensor inserted into the measuring application? Touching, non-contacting?

- mounting type: How is the sensor mounted?

- IP protection class and moisture resistance: tightness against liquid water and gaseous moisture ?

Cables and insulations

- measuring range: which temperature range ?

- connection: plug or wire end sleeves ?

- circuit type: two-, three- or four-wire ?

- accessories: plug connections, compression fittings or counterparts?

Our goal:The 0-error quality of your temperature sensor

One of the most important features of the temperature sensors produced by Testo Sensor GmbH is the proven stable long-term service life in continuous use in your application. Only with this qualified long-term stability over the entire planned lifetime of the temperature sensor, we can ensure that the specified temperature sensor type works error-free over the entire lifetime within the required specification.

To fulfil this high quality standard, two factors are decisive:

- Probe design: The measurement task in the application must be solved reliably and verifiably with lasting stability. This means that the temperature sensor must maintain the specified data in a permanently stable manner.

- Reproducibility: All probes produced in series must precisely match the qualified probe design. Exactly then when both factors are fulfilled, the necessary 0-fault quality will be achieved.

Design FMEA (D-FMEA) and Process FMEA (P-FMEA) ensure quality

Only a successfully passed Design FMEA and Process FMEA gives you the assurance that you will receive the necessary 0-fault quality from us.

Design-FMEA

This step is already done during the construction phase of your temperature sensor. Findings from the field tests are systematically included even before the start of series production. The aim of the design FMEA is to reliably identify possible weak points in the sensor design and in the individual components used of the temperature probes.

- Does the selected material withstand the loads over the service life?

- Are only materials used which are also approved for the application?

- Do the materials used work together perfectly?

Especially with regard to the thermal expansion behaviour?

Subsequently, potential weaknesses are evaluated according to their probability of occurrence and their impact on the overall design of the product. By the systematic recognition and elimination of errors we achieve the certainty that the respective temperature sensor type of Testo Sensor GmbH is optimally adapted to your application.

Process-FMEA

Once the sensor design has been qualified and is ready for series production, the process FMEA checks all production steps and examines them for risks of error. It must be ensured that the assembled temperature sensor corresponds exactly to the previously qualified sensor design after completion of all production steps.

- Which errors can theoretically be made at each production step?

- How would each possible error affect the behaviour of the temperature sensor and its function in the short and long term?

All potential errors are evaluated according to probability of occurrence and effect and then eliminated or reduced by optimizing the relevant process step. Ensuring is that every product made in the series process corresponds exactly to the product you have released and which has been qualified.

Get in contact with us.

Do you have any questions, comments, or suggestions?

Would you like to discuss your questions about a temperature probe project?

Contact us, we will be happy to assist you.

- Testo Sensor GmbH

- Testo-Str. 1 | 79853 Lenzkirch

- +49 7653 96597 0

- +49 7653 96597 99

- info@testo-sensor.de

- Neu: Testo Sensor Webshop

Your contact persons in sales

- Temperature probe for heat and cold meters

- Patrick Hermann

- +49 7653 96597 73

- phermann@testo-sensor.de

- Heating technology

- Nico Frey

- +49 7653 96597 74

- nfrey@testo-sensor.de

- Air conditioning and refrigeration

- Jannik Wolf

- +49 7653 96597 75

- jwolf@testo-sensor.de

- Temperature probes for HORECA applications

- Tobias Preiser

- +49 7653 96597 76

- tpreiser@testo-sensor.de

- Regional Sales Southern Europe

- Luca Malossi

- +49 7653 96597 77

- lmalossi@testo-sensor.de

- Plastics industry and mechanical engineering

- Tobias Löffler

- +49 7653 96597 49

- toloeffler@testo-sensor.de