Temperature probes for heat meter

Consistently rising energy costs and strict legal requirements demand highly accurate billing of the thermal energy used in heating or cooling systems.

One important component of heat and cold meters used for this purpose are the precise temperature probes for determining the temperature difference at the flow and return of the heating or cooling system.

Temperature probes for measuring the thermal energy, which are permissible for the demanding use in billing systems, are also available from us ready paired on request.

Testo Sensor GmbH not only produces temperature probes for heat and cold meters according to your specific specifications, but also keeps an eye on standards and guidelines for approval in accordance with regulations.

Our probe portfolio for heat meters and cold meters

This is what distinguishes our temperature probes for heat meters

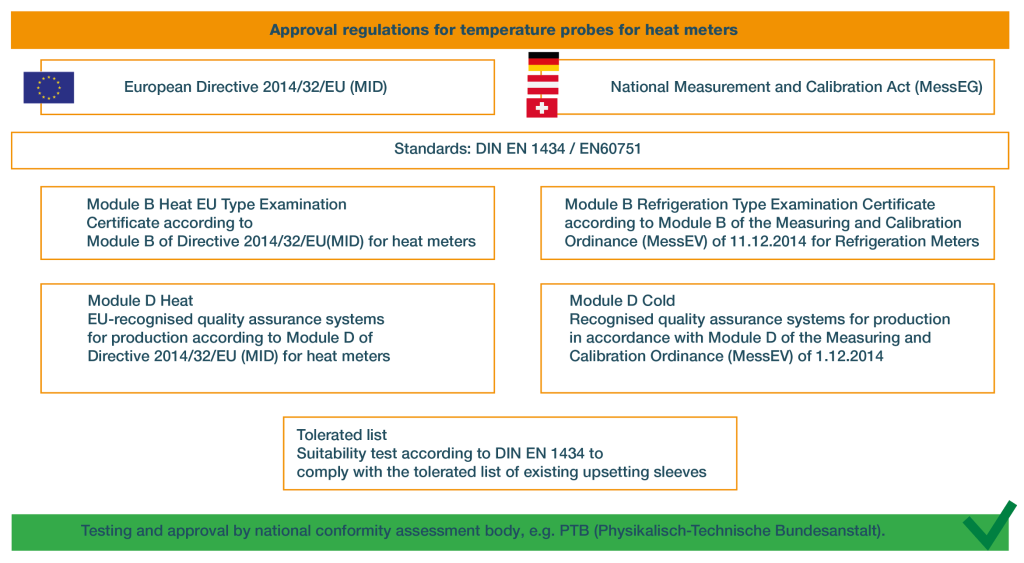

Our certifications & standards

- EU type examination certificate according to module B of the guideline 2014/32/EU (MID) for heat meters

- Type examination certificate according to module B of the Measuring and Calibration Ordinance (MessEV) of 11.12.2014 for cold meters

- Recognised production quality assurance systems according to Module D of Directive 2014/32/EU (MID)

- Recognised quality assurance systems for production in accordance with Module D of the Ordinance on Measurement and Verification (MessEV) of 1.12.2014

- Suitability test according to the list of pronounced toleration of stockpile crushes

- DIN EN 61326-1:2013

- DIN EN IEC 63000:2019-05

We can produce these temperature probes for heat meters for you

Temperature probe

for direct installation

- For direct installation

- Available with or without screw connection

- Fast response probe design

- Low minimum immersion depth required

- All probes are approved acc. to MID and MessEV

Please configure the probe according to your specification:

- Various sensors

- Different cables

- Diameter 5 / 5.2 or 6 mm

- Sleeve length 26 / 27,5 / 58 oder 60 mm

- With or without probe pairing

Temperature probe

for direct installation - fast responding

- For direct installation

- Available with or without screw connection

- Fast response probe design

- Low minimum immersion depth required

- All probes are approved acc. to MID and MessEV

Please configure the probe according to your specification:

- Various sensors

- Different cables

- Diameter 3,3 / 3,6 >> 5,4 mm

- Sleeve length 26 / 27,5 / 58 oder 60 mm

- With or without probe pairing

Temperature probe

for universal use

- Use for direct installation or use in immersion sleeve

- Universal mounting length via locking sleeves

- Fast response probe design

- Low minimum immersion depth required

- Probe is on the PTB's toleration list

- As Spare part set, incl. pairing & accessories

- All probes are approved acc. to MID and MessEV

Please configure the probe according to your specification:

- Various sensors

- Different cables

- Diameter 5 / 5.2 or 6 mm

- Sleeve length 26 / 27,5 / 58 oder 60 mm

- With or without probe pairing

Suitable accessories and services

Accessories for installing the temperature probes

- O-ring tool for removing and positioning sealing rings

- Foldable screw for direct installation

- Foldable screw for installation in immersion sleeves with internal thread

Measurement and pairing on our test bench

- Classic sensor pairing acc. to DIN EN 1434: measure, label, package as a pair

- Measured temperature probes: measure and label

- Self-service: Temperature probes, you measure and pair yourself

Our certifications & standards

Temperature probe pairing according to DIN 1434

We provide you the probes and on request also the pairing

Special guidelines and strict quality criteria apply to temperature probes in heat and cold meters. This makes the manufacturing process and especially the pairing process very complex.

With this video, we would like to give you a small insight into our fully automated pairing process.

We will show you how we have managed to make the process both effective and cost-efficient while still complying with all standards and specifications.

This ensures that we can not only meet the extremely high requirements of the PTB, but also significantly increase the sensor throughput per hour.

Our offer for you

- Reliable and versed development partner for new projects

- Quality and functionality that clearly exceeds the legal framework

- With us you have a direct contact person right down to the specialist departments (technician talks to technician)

- Our probes are approved, qualified and ready paired on request

- We have specifically optimised our temperature probes for use in conjunction with heat and cold meters

We offer you these benefits

- True alternative to established suppliers and full-fledged second source

- Our temperature probes are fully listed on the tolerated list of existing immersion sleeves.

- Uncompromising in quality and delivery reliability

- We have supplemented our production lines with a fully automated, high-precision pairing test stand

- We have successfully passed the PTB approval procedure and received all necessary type tests and cold approvals (DE / AT / CH)

- As a member, we actively participate in EMATEM and the standards committee.

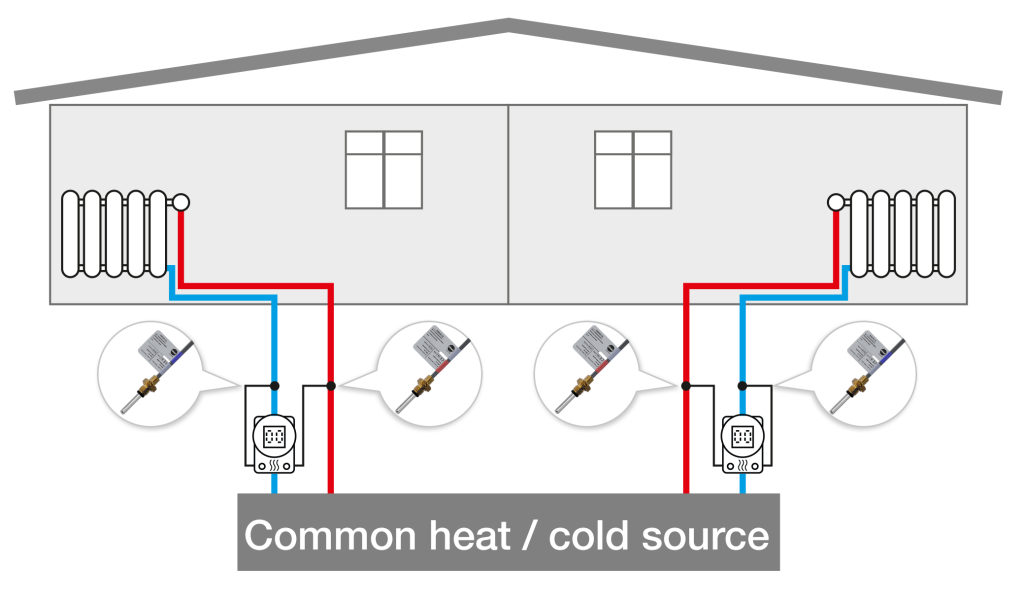

Application heat and cold metering

Why are heat and cold meters needed?

According to the Heating Costs Ordinance, the energy consumption of the individual consumers in buildings in which several consumers share a heating or cooling source must be accurately recorded for billing purposes.

This enables service charge billing according to the source, a fair distribution of costs and the identification of potential energy savings.

The use of highly accurate heat and cold meters for measuring the flow and return temperature of the heating water has been mandatory since 2014. The less accurate methods of calculating consumption used until then are no longer permitted.

The smallest measurement uncertainties in determining the temperature difference lead to errors in cost accounting. These must be avoided at all costs.

The temperature probes used are very tightly specified in their tolerances and must meet high legal requirements.

The temperature probes from Testo Sensor not only meet all legal requirements, but also exceed them in some points that are particularly important for the application, such as response time or long-term stability.

For precise measurement of the heat energy consumed in each case, two measured variables are decisive:

1. The flow measurement.

For this purpose, flow meters integrated in the heating and cooling circuits record the respective amount of water flowing through per time unit in a counter.

2. The temperature measurement.

For this purpose, a temperature probe is installed in the supply and return pipes of the heating water, which measures the temperature of the water in the respective pipe. The temperature difference results in the extracted heat energy, which can be assigned to the respective consumer.

Standards and guidelines for temperature probes for heat meters

Rely on our experience

Start of production

Heat meter probes ready for series production

Production line & pairing test stand in operation

Type approval

PTB issued MID type approval (module B)

Pairing process

PTB certifies the quality assurance system manufacturing and pairing process

(Module D)

Type examination certificate (cold)

MessEv (Module B)

Recognition in Austria & Switzerland

Portfolio expanded

Refrigeration approval for Switzerland & Austria

Inclusion in the tolerated list of existing immersion sleeves

The portfolio is growing

Expansion of the approval to include

fast-response probes for direct installation

Addition of suitable accessories

We are a member of Ematem

You can find the lectures from previous years here:

With this service package we will support you in your temperature sensor project.

We see ourselves as your partner and specialist in the field of OEM temperature sensors. You can always rely on having permanent and competent contact partners – for your technology, quality, logistics and purchasing.

At Testo Sensor you get everything from one source: the application-specific design, the samples and prototypes, right through to the production-ready article, the comprehensive qualification and the stable, high reproducible series production. As a skilled partner and OEM supplier to our customers, we deliver the complete package: the technical solution, the necessary quality, the appropriate supply logistics and the right price.

Specification

Together with you we develop the application-specific requirements that your temperature probe needs to fulfil.

Development

Our technicians work out the design of your temperature probe according to your given specifications.

Samples & Prototypes

We manufacture sample probes, prototypes and field test probes for you by hand and using pre-series tools.

Qualification

The production-ready probes are subjected to the necessary stress tests, endurance tests and functional tests in the laboratory.

Series production

Following acceptance of the qualified probes, we always go into series production with an informative 100% final functional test.

Logistics

100% on-time delivery rate, in accordance to your standards: KANBAN, consignment stocks or secured buffer storage facilities

Get in touch with us, we look forward to hearing from you.

- Testo Sensor GmbH

- Testo-Str. 1 | 79853 Lenzkirch

- +49 7653 96597 0

- +49 7653 96597 99

- info@testo-sensor.de

- Neu: Testo Sensor Webshop

Your contact persons in sales

- Temperature probes for heat meter

- Patrick Hermann

- +49 7653 96597 73

- phermann@testo-sensor.de

- Internal sales

- Tobias Preiser

- +49 7653 96597 76

- tpreiser@testo-sensor.de