- Start

- >

- Temperature probes for heat meters

- >

- Temperature probes universal use (DS / PS)

For heat meters and cold meters

For heat meters and cold meters

Temperature probes for direct installation

Steadily rising energy costs and strict legal requirements require highly accurate billing of the thermal energy consumed in heating or cooling systems.

An important component of the heat and cooling meters used for this purpose are the precise temperature probes for determining the temperature difference at the flow and return of the heating.

Temperature probes for measuring thermal energy, which are permissible for the demanding use in billing systems, are also available from us ready paired on request.

The Testo Sensor GmbH not only produces temperature probes for heat and cold meters according to your customer-specific specifications, but also keeps an eye on all standards and guidelines for proper approval.

Details for temperature probes for universal use (DS / PS)

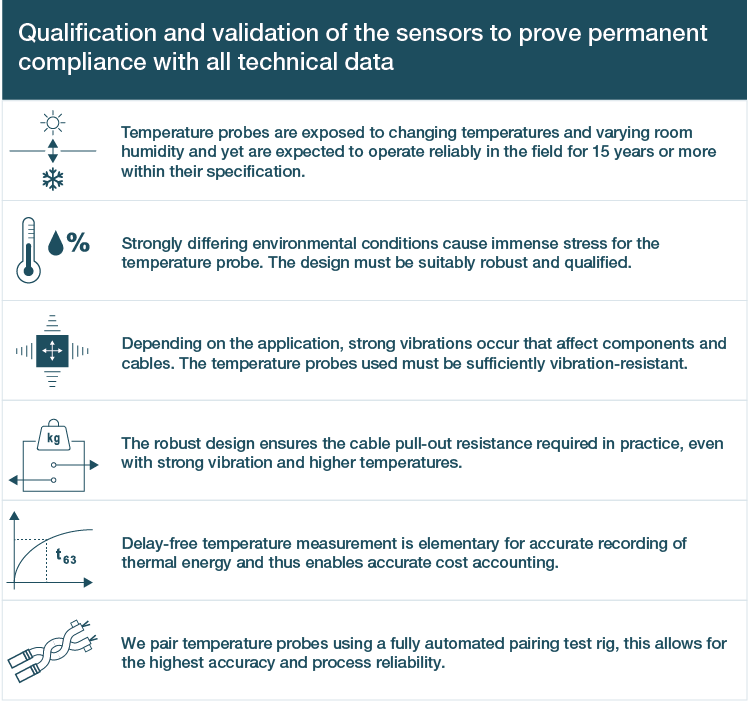

Technical requirement for heat meter probes (universal use)

To ensure that heating and cooling costs can be accurately allocated to the consumer and producer, a very accurate temperature measurement must take place. This follows strict legal requirements, because only in this way is a qualitative framework for reliable and comparable temperature measurements and thus heat and cold quantity counts possible.

Therefore, the conformity according to MID (Measuring Instruments Directive) of the EU, the European regulations for heat metering, is essential for our probes. There is currently no overarching European regulation in force for cold quantity metering; national regulations apply, e.g. according to the Measuring and Calibration Ordinance.

You can rest assured that the temperature probes from Testo Sensor GmbH fully meet or exceed all requirements for operation in conjunction with heat and cold quantity meters.

General information

| Measuring range (depending on sensor and connection cable) | ±0 °C bis +105 °C (PUR / PVC cable) |

| ±0 °C bis +130 °C (TPE cable) | |

| ±0 °C bis +150 °C (Silicone cable) | |

| Limit value temperature difference | 3 K to150 K |

| Response time | < 4s (depending on the design e.g. Ø 5.0 / 5.2 mm significantly faster) |

| Measurement stability | 10 years ( Please note recalibration cycles according to MID / MessEV) |

| Measuring elements | Please config (Pt100, Pt500 or Pt1000) |

| Tolerance | Class B according to EN60751 |

| Connection type | Two-Wire technology |

| Measuring principle | resistiv (resistance value) |

|

Maximum measurement current |

Pt100: 1178 μA at 2,5 m and 0,0095 Ohm/m |

| Pt500: 795 μA at 12,5 m and 0,0095 Ohm/m | |

| Pt1000: 562 μA at 255 m and 0,0095 Ohm/m | |

| Installation | Direct installation acc.to DIN EN 1434 or installation in immersion sleeves acc.to tolerance list |

| Minimum immersion depth | ≥ 20 mm |

| Max. pressure | P S 25 at flow velocity water 2 m/s |

| cable length according to DIN EN 1434 | Pt100 max 2,5 m | Pt500 max 12,5 m | Pt1000 max 25 m |

| Environmental conditions | Protection class: IP 65 (acc.to DIN 40050) | Electrical: E1| Mechanical: M3 | Climatic: -25 °C to +70 °C |

Configurable options

| Please configure your temperature probe for heat and cold meters | ||||||

| A – Measuring element | B – Ø Probe shaft | C – Mounting length | ||||

| Code | Meas.element | Accuracy | Code | Ø probe shaft | Code | Mount. length |

| A13 | Pt100 | Kl. B1) | B01 | 5,0 mm | C01 | 26,0 mm |

| A15 | Pt500 | Kl. B1) | B02 | 5,2 mm | C02 | 27,5 mm |

| A23 | Pt1000 | Kl. B1) | B03 | 6,0 mm | C03 | 38,0 mm |

| 1)dT = ±(0,30 °C + 0,005 · T) acc. to IEC 751 / EN 60751 | Conn. type: 2-wire | C04 | 60,0 mm | ||||

| Other probe shaft Ø between 5.0 and 6.0 mm as well as other mounting lengths and customised screw connections are available on request. | ||||||

| J – Process connection | D – Material connection cable | ||||||||

| Code | Standard | Code | Conn. | Color | From | To | Out | Color | Q mm2 |

| J00 | without screw connection | D01 | 2-wire | black | ±0°C | +105°C | PVC | rt, ws | 0,22 |

| D02 | 2-wire | black | ±0°C | +150°C | Silicone | rt, ws | 0,22 | ||

| J02 | M10 x 1 incl. locking screw & sealing device |

D03 | 2-wire | black | ±0°C | +130°C | TPE | rt, ws | 0,22 |

| D04 | 2-wire | black | ±0°C | +105°C | PUR | rt, ws | 0,22 | ||

| Further or customised screw fittings are available on request | |||||||||

| E – Length | G – End seleeves | P – Standard | |||

| Code | Length | Code | Standard | Code | Standard |

| E01 | 1,5 m | G01 | Wire end ferrules (standard) | P00 | not paired |

| E02 | 2,5 m | G02 | Tin-plated connection leads (only for probes permanently connected to the calculator) |

P01 | paired according to DIN EN 1434 |

| P02 | paired according to DIN EN 1434 with conformity assessment / marking according to MID (heat) |

||||

| P04 | paired according to DIN EN 1434 with conformity assessment / marking according to MessEG (cold Austria) |

||||

| We offer other cable lengths between 0.3 m and 25 m in increments of 0.5 m. Please note the maximum lengths (depending on the sensor): Pt100 max 2.5 m | Pt500 max 12.5 m | Pt1000 max 25 m |

|||||

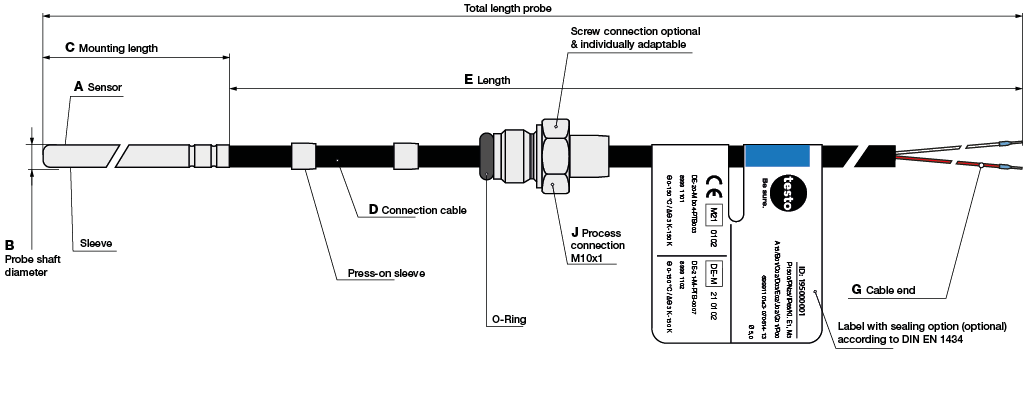

Technical drawing & mounting instructions

| Technical Drawing | |

|

Poss. configuration A = Meas. elements

B = Ø Probe shaft

C = Mount. length

D = Cable material

E = Cable length

J = Process connection

G = Wire end

P = Standard

|

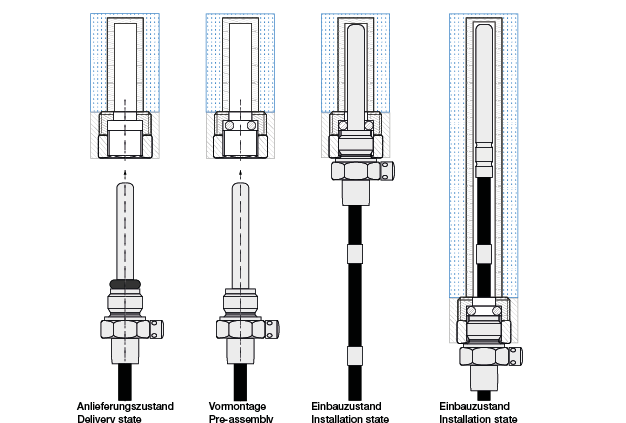

| Installation instructions | ||

| The installation of temperature probes in pipelines (qp ≤ 6) must be carried out directly in new installations in Germany. Please carry out direct installation of temperature probes in accordance with DIN EN 1434-2 and the technical guideline TR-K8 (see following figure). |

|

|

|

Our certifications & standards

- EU type examination certificate according to module B of the guideline 2014/32/EU (MID) for heat meters

- Type examination certificate according to module B of the Measuring and Calibration Ordinance (MessEV) of 11.12.2014 for cold meters

- Recognised production quality assurance systems according to Module D of Directive 2014/32/EU (MID)

- Recognised quality assurance systems for production in accordance with Module D of the Ordinance on Measurement and Verification (MessEV) of 1.12.2014

- Suitability test according to the list of pronounced toleration of stock immersion sleeves

- DIN EN 61326-1:2013

- DIN EN IEC 63000:2019-05

Data sheets for temperature probes for heat meters (universal use)

Your contact person for temperature probe on heat meters

- Patrick Hermann

- +49 7653 96597 73

- phermann@testo-sensor.de

- Direkt einen Termin vereinbaren

- Testo Sensor GmbH

- Testo-Str. 1 | 79853 Lenzkirch

- +49 7653 96597 0

- +49 7653 96597 99

- info@testo-sensor.de

- Neu: Testo Sensor Webshop