- Home

- >

- Service Package

- >

- Series production

Series production

Our manufacturing philosophy

- Semi-automated series production forms the necessary basis for manufacturing even larger quantities in zero-defect quality and, at the same time, economically.

- The modular production lines also enable the efficient production of smaller quantities, since the production lines can be converted very quickly and thus cost-effectively.

- Movable production modules, such as soldering, potting or sensor positioning in the probe sleeve, support the adaptation of all production lines to changing requirements. Fluctuations in demand of +/-20% for each probe type can be cushioned as standard and without placing particular strain on production.

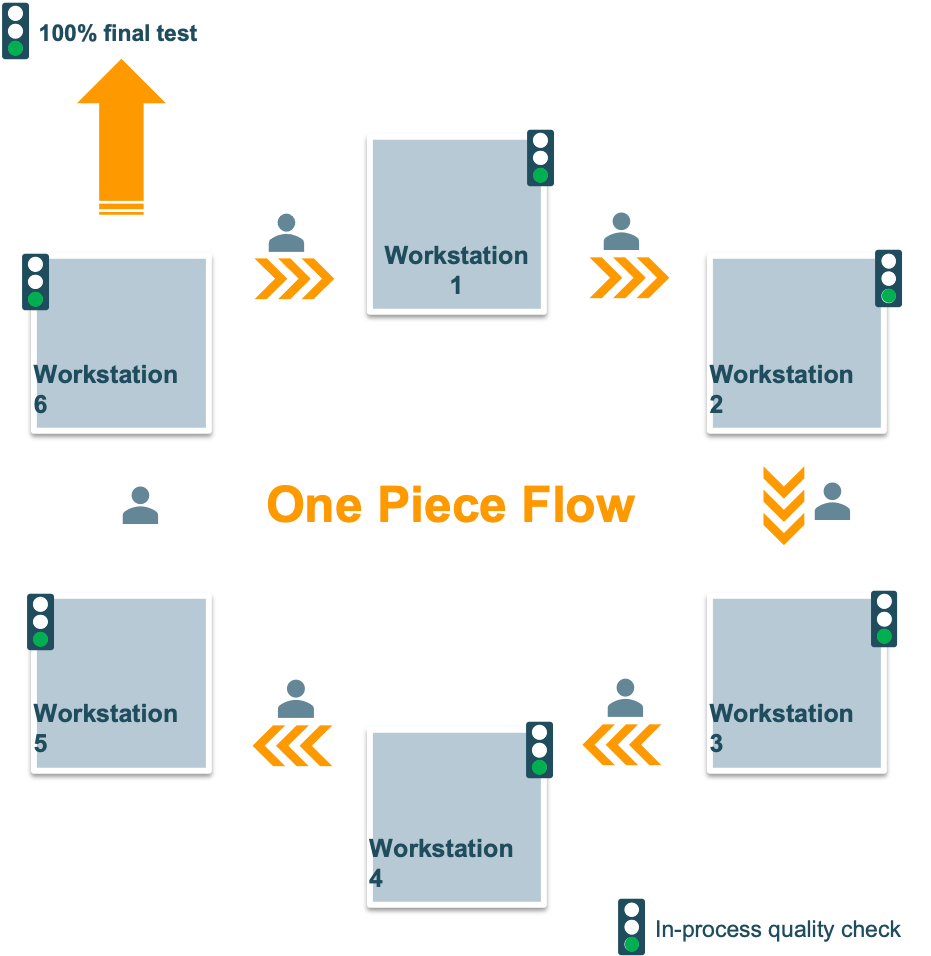

- The production lines are designed in accordance with the philosophy of One-Piece-Flow. This means that in each case, each employee manufactures the entire probe. By removing or adding employees, the capacity and thus the output of each line can be quickly adapted to any change in demand.

- A final test is always, i.e. 100%, carried out. This ensures accuracy, correct positioning of the sensor, complete filling of the sleeve and the required response time.

A semi-automated, modular series production of temperature probes has lots of advantages:

- The qualified probe design can be manufactured with a high degree of reproducibility, especially in the case of large quantities.

- In-process quality checks can be carried out efficiently during production.

- A field abnormality rate of less than 400 ppm can be achieved (zero-defect quality standard)

- A complete, informative and documented 100% final test ensures the quality standard once again before the probes are packed and shipped.

- The modular production lines enable fast adaptation of production steps to achieve technically modified temperature probes.

Quality management

100% Final test

A final test is always, i.e. 100%, carried out. This ensures:

- accuracy

- correct positioning of the sensor,

- complete filling of the sleeve

- the required response time

Certificates

- We organize our processes in accordance with international standards.

- We are ISO EN 9001 (2015) certified.

- Our manufacturing facility in China is also ISO 14001 certified.

Get in contact with us.

Do you have any questions, comments, or suggestions?

Would you like to discuss your questions about a temperature probe project?

Contact us, we will be happy to assist you.

- Testo Sensor GmbH

- Testo-Str. 1 | 79853 Lenzkirch

- +49 7653 96597 0

- +49 7653 96597 99

- info@testo-sensor.de

- Neu: Testo Sensor Webshop

Your contact persons in sales

- Temperature probe for heat and cold meters

- Patrick Hermann

- +49 7653 96597 73

- phermann@testo-sensor.de

- Heating technology

- Nico Frey

- +49 7653 96597 74

- nfrey@testo-sensor.de

- Air conditioning and refrigeration

- Jannik Wolf

- +49 7653 96597 75

- jwolf@testo-sensor.de

- Temperature probes for HORECA applications

- Tobias Preiser

- +49 7653 96597 76

- tpreiser@testo-sensor.de

- Regional Sales Southern Europe

- Luca Malossi

- +49 7653 96597 77

- lmalossi@testo-sensor.de

- Plastics industry and mechanical engineering

- Tobias Löffler

- +49 7653 96597 49

- toloeffler@testo-sensor.de