Specialist for temperature measurement technology

Specialist for temperature measurement technology

Application-specific

temperature probes

As a global specialist and OEM supplier of temperature probes and thermocouples, we design the ideal probe for your specific measuring task by working closely with our customers.

Here, you get everything from one source:

the application-specific design, the samples and prototypes, right through to the production-ready article, the comprehensive qualification and the stable, high reproducible series production.

About Testo Sensor GmbH

Testo Sensor GmbH was founded in 2010 as a subsidiary of Testo SE & Co. KGaA. As measuring technology experts, we have specialized in the development and manufacture of customer-specific temperature probes. As a skilled partner and OEM supplier to our customers, we deliver the complete package: the technical solution, the necessary quality, the appropriate supply logistics and the right price.

We support our customers in all project steps from specification through the development phase to series production. We develop, qualify and manufacture the temperature sensors according to the specifications of our customers. Furthermore, we ensure the required quality and functionality through design and process FMEA’s.

What sets Testo Sensor GmbH apart?

- Close, partner-like cooperation with our customers from the specification phase onwards

- Competent advice and cooperation in technology, quality, purchasing and logistics

- Specialist in developing application-specific OEM temperature probes

- Focus on a few core industries

- Cost-efficient production with a high level of reproducibility through semi-automated production lines

- Traceability in the manufacturing process that is accurate to the nearest hour

- Effective QM system for zero-defect quality (< 400 ppm field failure rate)

- 100% on-time delivery rate with the aid of suitable buffer storage facilities

- Logistical accessibility to your system, such as Kanban, SAP-EDI, consignment or buffer stocks

Our service package for you

We see ourselves as your partner and specialist in the field of OEM temperature sensors. You can always rely on having permanent and competent contact partners – for your technology, quality, logistics and purchasing.

At Testo Sensor you get everything from one source: the application-specific design, the samples and prototypes, right through to the production-ready article, the comprehensive qualification and the stable, high reproducible series production. As a skilled partner and OEM supplier to our customers, we deliver the complete package: the technical solution, the necessary quality, the appropriate supply logistics and the right price.

Specification

Together with you we develop the application-specific requirements that your temperature probe needs to fulfil.

Development

Our technicians work out the design of your temperature probe according to your given specifications.

Samples & Prototypes

We manufacture sample probes, prototypes and field test probes for you by hand and using pre-series tools.

Qualification

The production-ready probes are subjected to the necessary stress tests, endurance tests and functional tests in the laboratory.

Series production

Following acceptance of the qualified probes, we always go into series production with an informative 100% final functional test.

Logistics

100% on-time delivery rate, in accordance to your standards: KANBAN, consignment stocks or secured buffer storage facilities

We are already engaged in these industries.

We aim to convince you with our technical expertise. Which is why we focus on just a few industries. There our goal is to be the leading supplier of temperature probes and to convince you in each project.

For each of these areas you can rely on a broad portfolio of different temperature sensor designs whose design has been particularly and elaborately qualified for the application and measuring task. For this reason, the necessary qualification programs and our own laboratory and partner network are highly specialized in these applications.

Temperature probes for heating, air conditioning and refrigeration technology

Temperature probes for white goods

Temperature probes for machine building industries

Temperature probes for heat and cold meters

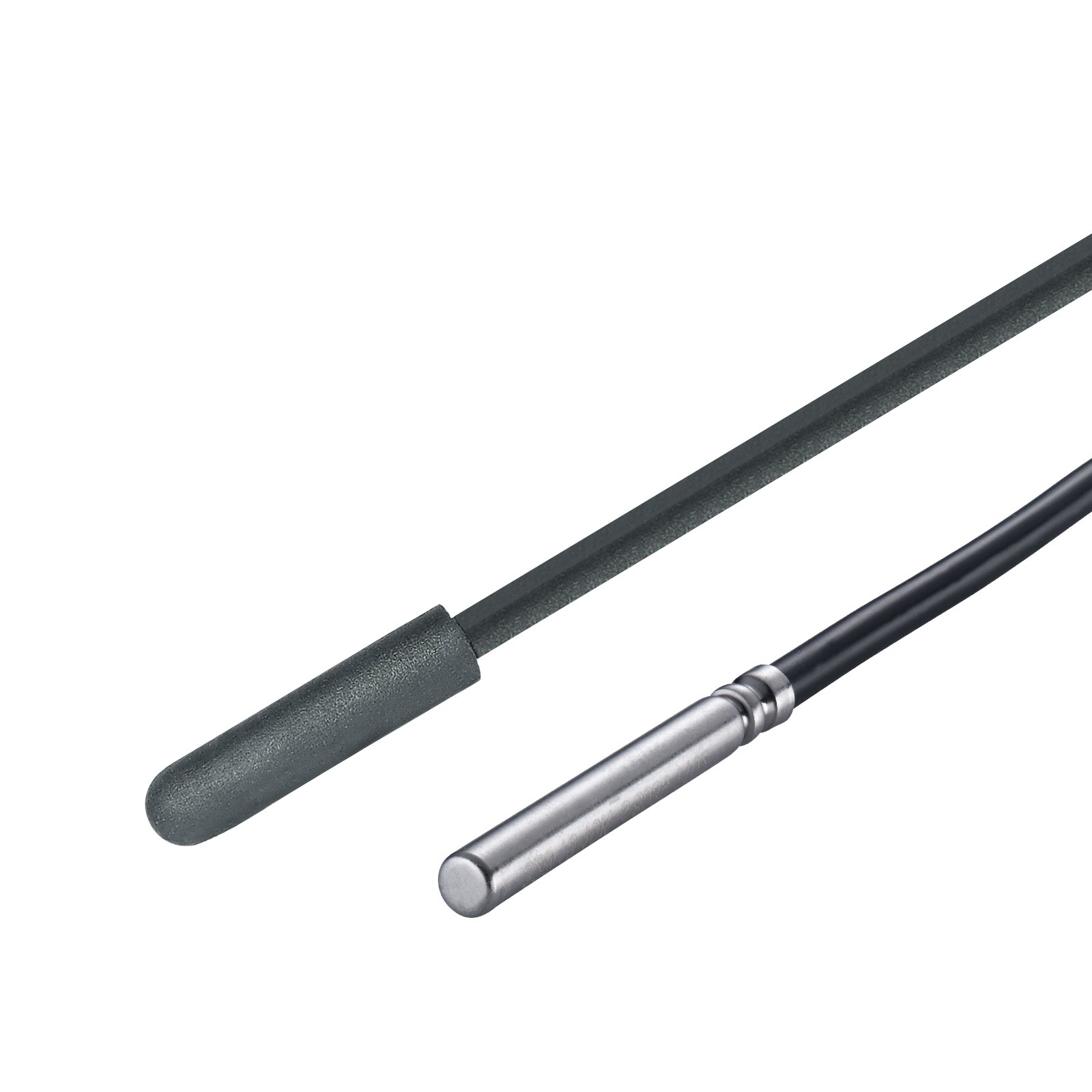

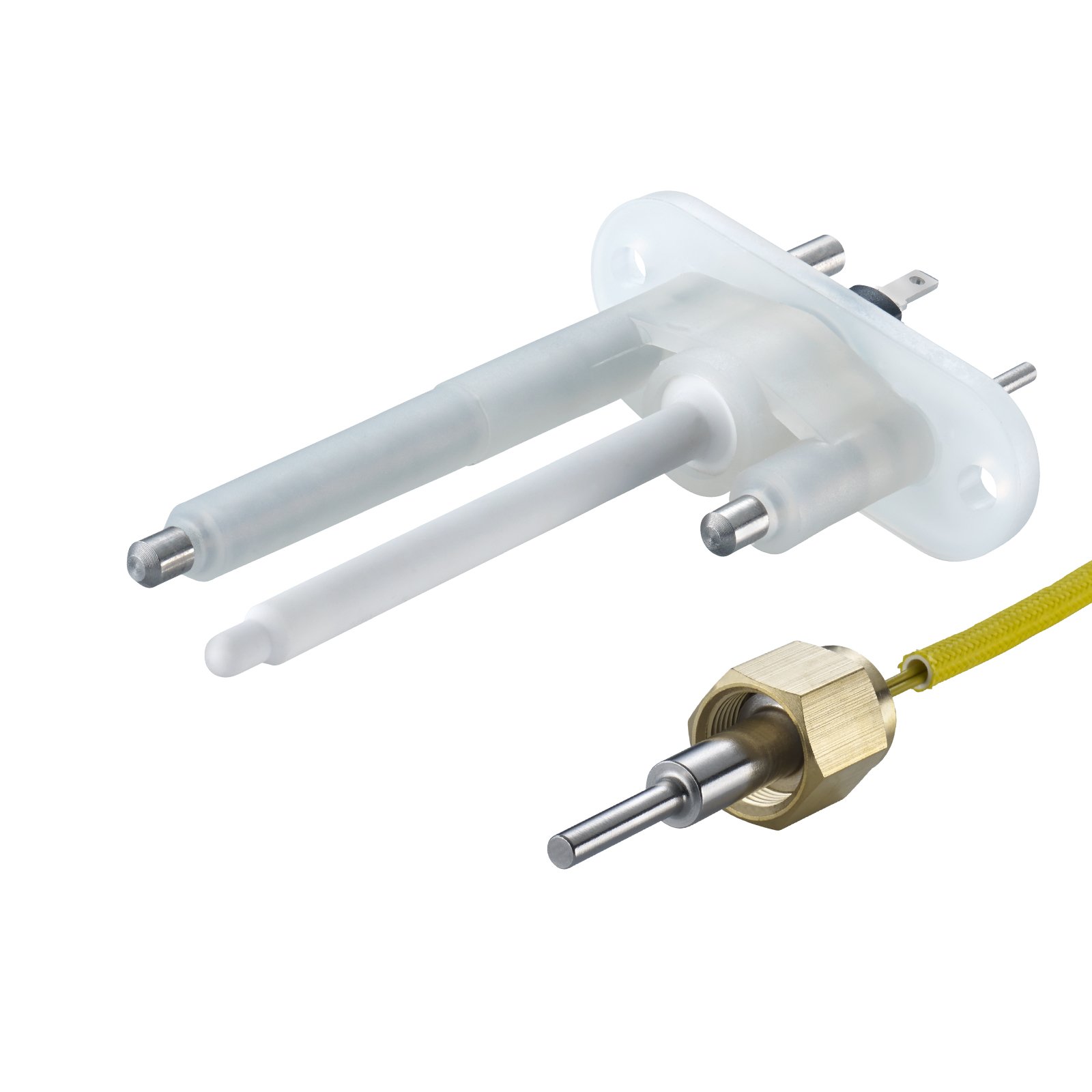

Temperature sensor portfolio

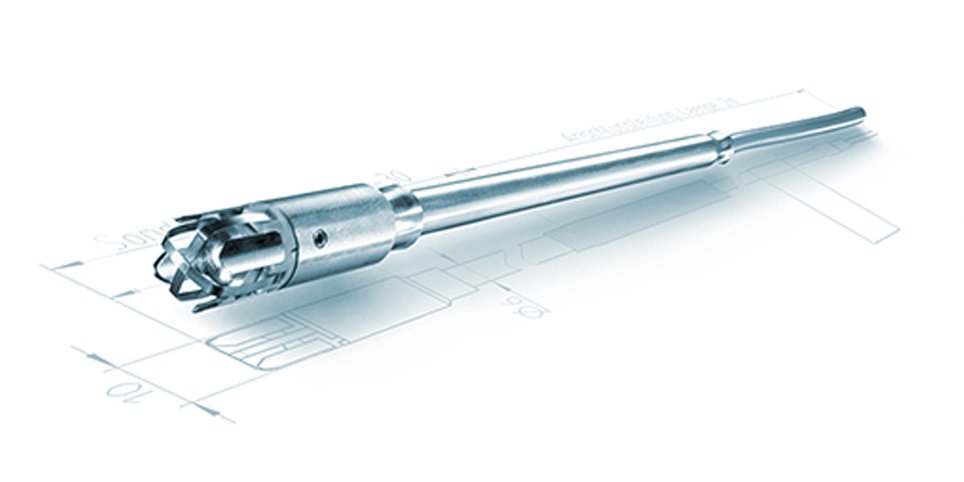

As versatile as your applications are also temperature sensors that might be used for these applications. For this reason, the exact specifications need to be elaborated and each sensor design must be extensively qualified for the respective application. Only this ensures that the sensor fully meets the subsequent requirements in the field and reliably fulfils the given specification over the entire expected service life.

Testo Sensor offers you the benefit of numerous already constructed and qualified designs for different sensor types and applications. Even if your application does not exist yet, we can support you as we are specialized in the design and manufacturing of qualified OEM temperature sensors that are proven to meet your requirements.

- All

- Temperature probes

- Temperature probes for machine building industry

- Temperature probes for heating, air conditioning and refrigeration technology

- Temperature probes for White goods

- Temperature probes for heat meters

Get in contact.

- Testo Sensor GmbH

- Testo-Str. 1 | 79853 Lenzkirch

- +49 7653 96597 0

- +49 7653 96597 99

- info@testo-sensor.de

- Neu: Testo Sensor Webshop

Frequently asked questions

The performance characteristics and the conditions under which they must be proven are decisive for the qualification program that a temperature sensor must undergo. This ensures that the sensor fully meets the subsequent requirements in the field and reliably fulfils the given specification over the entire expected service life.

A qualification consists of various predefined stress tests to which a defined sample of the respective temperature sensor type is exposed.

Which kind of stress tests we offer, you find here: qualification

When we specify your required temperature sensor, we take into account all your requirements regarding the technical data of the temperature sensor and define all necessary qualification measurement series. Only when these stress tests have been passed successfully is the long-term reliability and long-term stability proven. Furthermore, during series production it has to be ensured that each produced temperature sensor is exactly and in every detail identical to the previously qualified sensors.

To prove the vibration resistance of a temperature sensor, a sample of this type of sensor is exposed to acceleration forces of up to 20g in the x, y and z axes on a vibration table in accordance with the standard (i.e. amplitudes to be set according to the standard and frequencies to be passed through). This hard vibration causes enormous forces, which affect the clamped temperature sensors mechanically.

If the sensor has been perfectly designed and manufactured in advance, 100% of the sample will survive this test without a single failure.

If specially designed sleeves made of metal or ceramics are assembled in combination with the right sensors (thermistors or platinum resistors), thermally conductive fill materials and the right geometries, response times (T63) of less than 1 second are indeed achievable nowadays.

Prerequisite for this: the necessary immersion depth in the medium is ensured.

In particularly critical, e.g. safety-relevant applications, so-called duplex sensors are used. In this case, two similar sensors (thermistors or platinum resistors) that monitor each other are installed in one single temperature sensor. If the difference between the two output resistance values exceeds a defined value, the connected control system switches off the respective system.