- Home

- >

- temperature probes

- >

- Pipe contact probe

Firm seating at the measuring point

Firm seating at the measuring point

Pipe contact probe

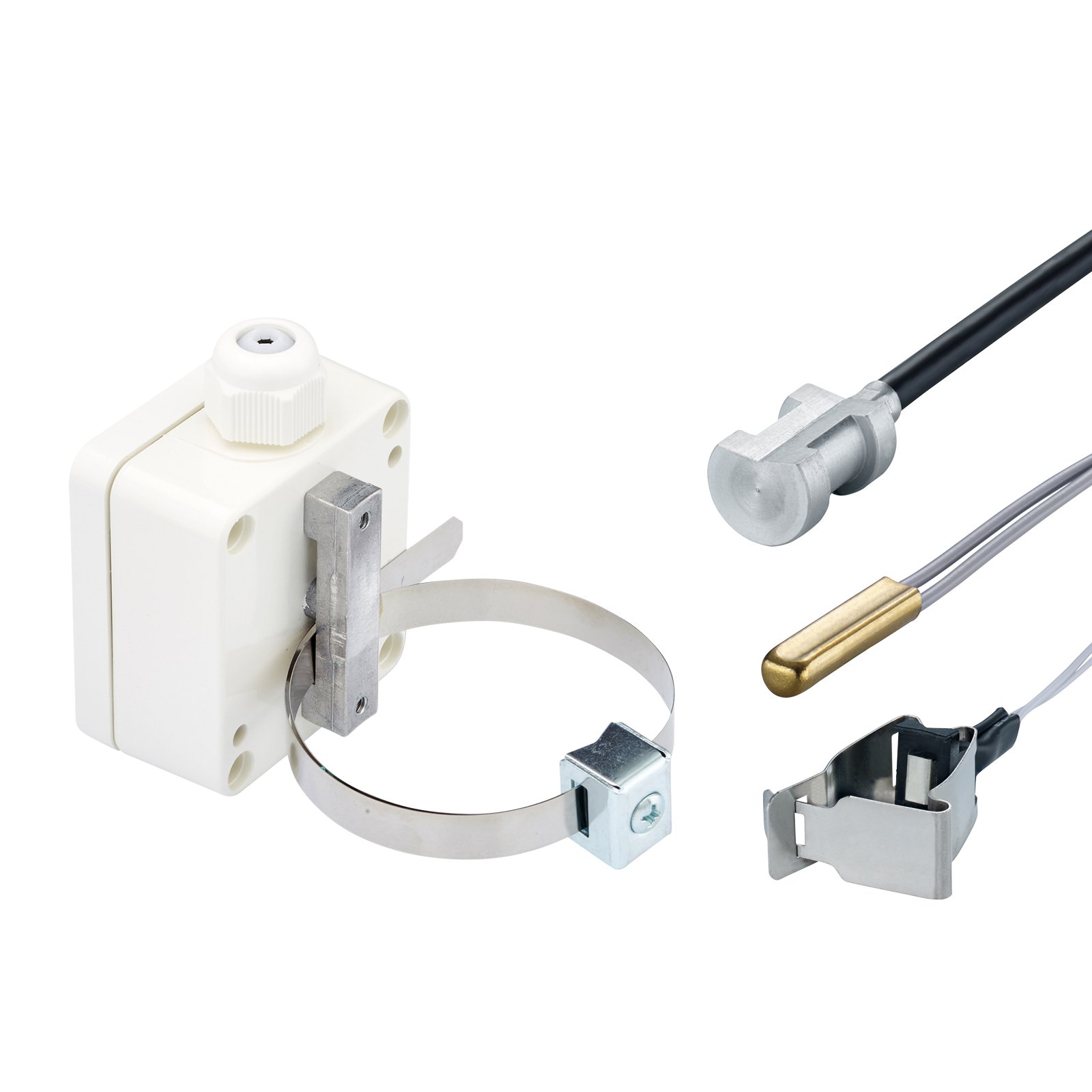

Our pipe contact probes are designed for surface temperature measurements on pipes such as the flow and return in heating systems. Correctly adjusted flow and return temperatures are elementary for the efficiency of the entire heating circuit. If the flow temperature is too low, the room will not get warm. On the other hand, if it is too high, too much energy is wasted, causing unnecessarily high heating costs.

The design of the contact sensors is decisive. This allows them to be ideally thermally coupled to the measuring point. Each measuring task requires a perfectly adapted geometry in order to increase the contact area and reduce the response time. We advise you on the optimum geometry for your application and adapt the contact temperature probes individually to your measuring task.

Pipe contact probe

Technical requirements Pipe contact probes

Pipe contact probes use surface temperature measurement to detect the water temperature at the flow and return pipe of the heating system. This type of measurement has the advantage that the temperature sensors are easy to install and can be maintained or replaced fast and efficiently. At the same time, surface temperature measurement is significantly slower and less accurate than direct, inverse measurement.

For this reason, the correct and uniform positioning of the contact sensor on flow and return pipes is important in order to keep measurement errors as small as possible. For this purpose, we deliver all our pipe contact sensors with a quick-release strap, which couples the temperature sensor thermally optimally. If necessary, the heat transfer can be further improved by the use of heat-conducting paste, which is also included. We offer these additionally as accessories.

Pipe contact probes should be of high quality and at the same time cost-effective and yet have a long service life of 15 years. They must work reliably and within the specification during its entire service life.

Design Pipe contact probes

As pipe contact probes usually cable probes with contact body or contact probes with housing are used. The shape and the material of the contact body or sleeve is decisive for the response time of the contact sensor.

Response time is mainly influenced by the material of the sleeve or contact body as well as by the heat transfer to the measuring element. Pipe contact sensors with an aluminium contact body or a brass contact body are particularly suitable. The reason is that the thermal conductivity of aluminium is many times higher than that of stainless steel. With brass elements, the thermal conductivity is still about half that of aluminium.

Each measuring task requires a perfectly adapted geometry to increase the contact surface and reduce the response time. We advise you on the optimum geometry for your application and adapt the design of the contact temperature sensors to this. Your individual specification also determines whether we manufacture the temperature sensors with cables and wire end sleeves or the appropriate connectors for your application. We would be pleased to advise you and suggest a suitable, qualified sensor type.

Data sheet Pipe contact probes

Sales person Pipe contact probes

- Testo Sensor GmbH

- Testo-Str. 1 | 79853 Lenzkirch

- +49 7653 96597 0

- +49 7653 96597 99

- info@testo-sensor.de

- Neu: Testo Sensor Webshop